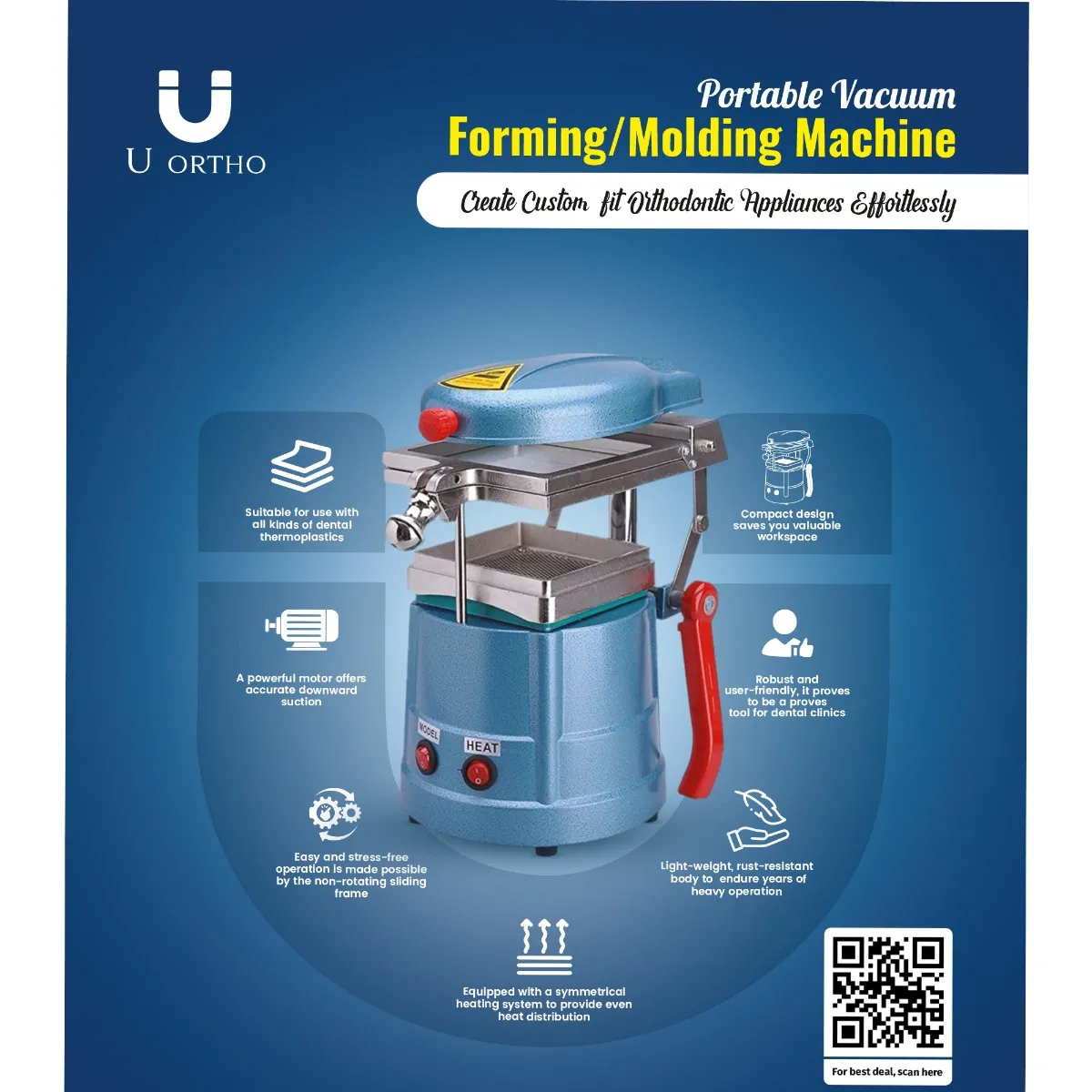

Dental Vacuum Forming/Molding Machine is a versatile and essential tool used in the field of dentistry for the fabrication of various dental appliances. It is designed to create precise imprints of opposing bites and fabricate appliances such as sports mouth guards, bleaching trays, orthodontic appliances, and indirect bonding trays. This machine utilizes vacuum technology to achieve accurate and consistent results. It consists of a heating element and a vacuum chamber. The heating element evenly heats a thermoplastic sheet, making it pliable and ready for molding. Once the thermoplastic sheet reaches the desired temperature, it is quickly transferred to the vacuum chamber. The vacuum chamber creates a negative pressure environment that enables the thermoplastic sheet to conform tightly around a dental model or an impression of the patient’s teeth. This process ensures a snug fit and precise replication of the dental anatomy. U Ortho Dental Vacuum Forming/Molding Machine is user-friendly and adjustable, allowing dental professionals to customize the fabrication process based on the specific requirements of each patient. It offers control over temperature, vacuum strength, and timing, enabling the production of high-quality dental appliances.

The primary applications of this machine include:

- Sports Mouth Guards: Dental professionals can use the machine to fabricate custom-fit mouth guards that provide maximum protection for athletes engaged in contact sports.

- Bleaching Trays: This machine enables the creation of custom bleaching trays that perfectly fit a patient’s teeth. These trays are used to hold bleaching agents during at-home teeth whitening treatments, ensuring even distribution and optimal results.

- Orthodontic Appliances or Retainers: The machine is instrumental in producing orthodontic appliances, such as retainers or aligner trays. These appliances are customized to maintain the position of teeth after orthodontic treatment or to facilitate gradual tooth movement.

- Indirect Bonding Trays: Indirect bonding trays are used in orthodontics to accurately position and bond brackets onto a patient’s teeth. The vacuum molding machine allows for the creation of precise trays that facilitate efficient and accurate bracket placement, saving time and improving treatment outcomes.

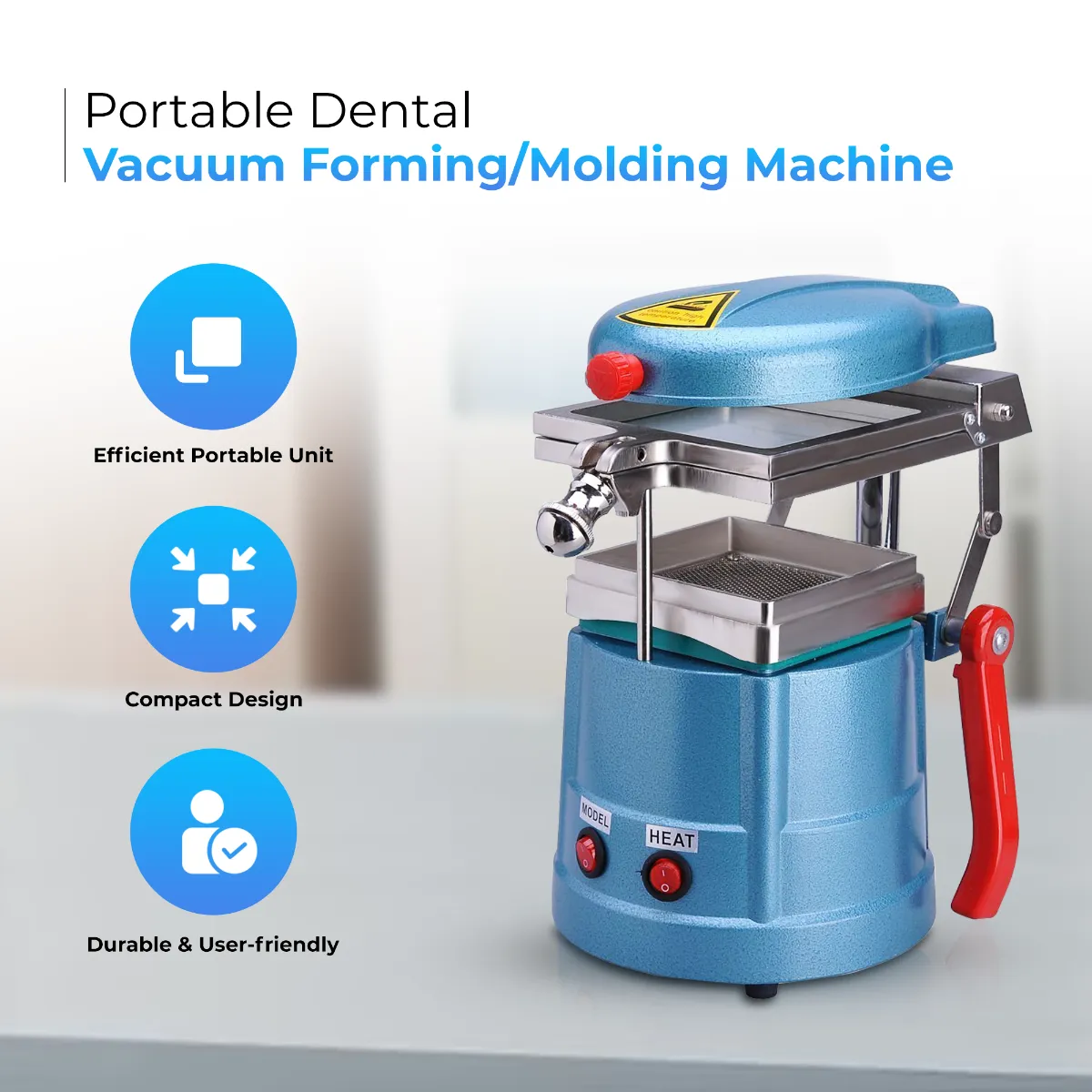

Features

- Heating Element: Evenly heats the thermoplastic sheets, making them pliable and ready for molding.

- Vacuum Chamber: The machine has a vacuum chamber where the thermoplastic sheet is placed for molding. It creates a negative pressure environment to ensure a tight and precise fit around the dental model or impression.

- User-Friendly Interface: The machine features a user-friendly interface with clearly labeled buttons or switches for easy operation.

- Adjustable Platform: The machine typically has an adjustable platform where the dental model or impression is placed, allowing for proper alignment and positioning.

- Compatibility with Various Dental Appliances: The machine is designed to accommodate the fabrication of different dental appliances such as sports mouth guards, bleaching trays, orthodontic appliances, and indirect bonding trays.

- Compact and Durable Design: The machine is compact and sturdy, making it suitable for use in dental clinics or laboratories. It is built to withstand frequent use and provide long-lasting performance.

TECHNICAL SPECIFICATIONS :

- Dimension: 25x21x30cm

- Thermo forming material size: 5″ x 5″

- Voltage: 110V/60Hz

- Power supply: 1000W

- Machine weight: 6kg

Direction of use

- Safety Precautions:

- Before using the machine, ensure that you have read and understood the instructions and safety guidelines.

- Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself during the process.

- Prepare the Thermoplastic Sheets:

- Select the appropriate thermoplastic sheet for the desired dental appliance.

- Cut the sheet into the required size and shape, allowing for proper coverage of the dental model or impression.

- Preheat the Machine:

- Plug in the machine and turn ON the power.

- Adjust the temperature settings based on the recommendations provided by the manufacturer and the type of thermoplastic material being used.

- Allow the machine to preheat until the desired temperature is reached. This usually takes a few minutes.

- Position the Dental Model or Impression:

- Place the dental model or impression on the platform of the machine, ensuring that it is centered and properly aligned.

- Place the Thermoplastic Sheet:

- Carefully place the pre-cut thermoplastic sheet over the dental model or impression.

- Make sure that the sheet covers the entire area to be molded and that there are no wrinkles or folds.

- Engage the Vacuum:

- Close the lid or cover of the machine securely, creating a sealed chamber.

- Activate the vacuum function by pressing the appropriate button or switch.

- The vacuum will create suction, pulling the thermoplastic sheet tightly around the dental model or impression.

- Molding Process:

- Monitor the molding process closely.

- The thermoplastic sheet will soften and start to conform to the shape of the dental model or impression.

- The exact time required for molding will vary depending on the type of thermoplastic material and the manufacturer’s instructions. Typically, it takes a few seconds to a minute.

- Release the Vacuum and Remove the Molded Appliance:

- Once the desired molding time has elapsed, release the vacuum by turning off the machine or pressing the appropriate button.

- Open the lid or cover of the machine, exposing the molded appliance.

- Carefully remove the molded appliance from the dental model or impression, ensuring that it retains its shape and accuracy.

- Trimming and Finishing:

- Trim any excess material from the molded appliance using dental instruments or scissors, following the specific instructions for the intended dental appliance.

- Smooth and finish the edges of the appliance as necessary, ensuring patient comfort and functionality.

- Clean and Maintain the Machine:

- After each use, clean the machine.

- Remove any residual material or debris from the vacuum chamber and heating element.

- Store the machine in a safe and dry place to prevent damage.

Reviews

There are no reviews yet.